commercial garage doors Services

Commercial Garage Door Operators

The right type of commercial garage door operator is dependent on the type of commercial garage door and use. Each facility has specific door use types, cycles needed for opening and closing and the speed the door must open and close based on the traffic flow and type.

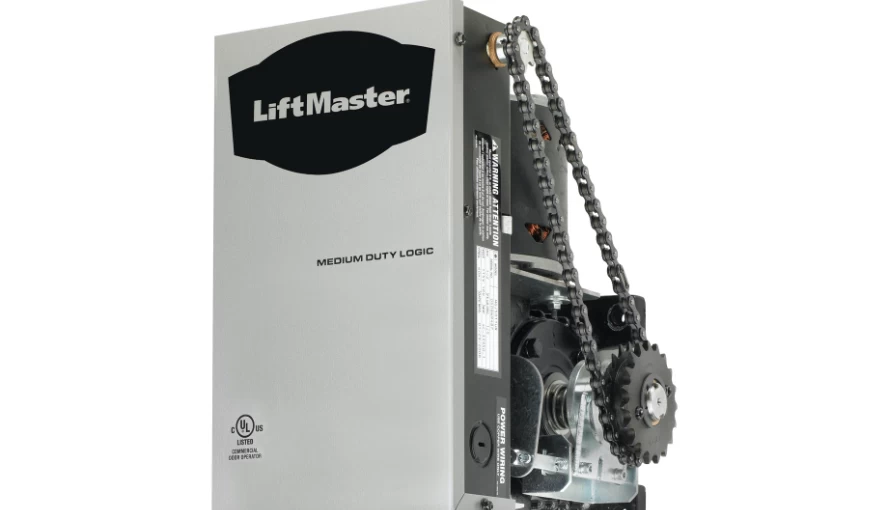

Commercial garage door operators come in light duty, medium duty, heavy duty, industrial duty, fire-rated door models and specialty commercial operators and models for overhead and dock doors. Other models types include trolley operators, hoist operators for release options and jackshaft models. Trolley openers are typically used for standard lift sectional doors. Major manufacturers include LiftMaster, Micanan, Linear, Janus Pantheon and the Dominator. LiftMaster is Garage Door Medics preferred manufacturer.

The following operators are listed to give ideas and use types for each.

Light Duty Commercial Garage Door Operators

Operators that are used for smaller, lighter rolling commercial doors requiring less than 25 cycles per day and certain models designed for limited-space settings. Ideal installation sites include small warehouses, self-storage facilities, and facility’s that have counter shutter doors. These operators come with commercial photo eyes. If it is a dock door operator or a commercial opener used for sectional doors, the kit includes a cable tension monitor kit. Micanan commercial operators have a bit higher cycle count per hour as well. Jackshaft and trolley models are available too.

Types of Doors

Commercial Rolling Sheet, Commercial Sectional Garage Door, Security Grille, Counter Shutters and Dock Doors

Max Cycles Per Day

LiftMaster – Maximum 10 cycles per hour; Fewer than 25 cycles per day

Micanan – Maximum 15 cycles per hour

Compatible Accessories (Model Dependent)

Automatic Garage Door Lock

Garage Door Opener Battery

Light Curtain

MyQ Remote Led Light (LiftMaster)

Remote Control

Loop Detectors, Probes and Radar

Medium Duty Commercial Garage Door Operators

Medium duty operators are best suited for increased door weight and frequency of cycles. They are install for medium duty commercial door applications requiring less than 50 cycles per day. Ideal installation sites include moderate parking garages, warehouses and industrial facilities. A good rule of thumb is to choose a commercial operator that has 2x the cycles as parking spots. For example, if you have 10 parking spots, you should choose an operator that can do at least 20 cycles per day minimum. Medium duty operators come with a 3-button station and commercial photo eyes. Jackshaft and trolley models are available too.

Types of Doors

Commercial Rolling Sheet, Commercial Sectional Garage Door, Security Grille, Counter Shutters and Dock Doors

Max Cycles Per Day

Maximum 12 cycles per hour; Fewer than 50 cycles per day

Compatible Accessories

Single Button Control

Auxiliary Limit Switches

Interlock Switch

Remote Control

Loop Detectors, Probes and Radar

Heavy Duty & Industrial Duty Commercial Garage Door Operators

When deciding between the strength of commercial garage door operators, heavy duty operators are designed for extreme use. These operators are manufactured to allow continuous duty cycles. They are ideal for very large parking facilities or extremely high use commercial garage doors.

Similar to heavy duty commercial garage door operators, industrial duty commercial door operators are best for industrial applications with larger sectional overhead doors, rolling doors and grilles. They have multiple power options 1/3, 1/2, ¾ and 1 HP. These operators are manufactured to allow continuous duty cycles and have dual voltage connections and customizable voltage to meet job requirements – single phase, 3-phase and discrete models.

Both types have side mounts to the wall for vertical or high-lift doors. Jackshaft and trolley models are available too.

Types of Doors

Rolling Steel Garage Doors, Parking Garage Security Grilles and Commercial Sectional Garage Doors.

Max Cycles Per Day

Maximum 25-60 cycles per hour during peak usage depending on the manufacturer and model, greater than 90 cycles per day.

Compatible Accessories

Single Button Control

Auxiliary Limit Switches

Interlock Switch

Remote Control

Loop Detectors, Probes and Radar

Commercial Fire-Rated Garage Door Operators

Fire-rated operators are designed to work with fire doors so that when a fire alarm is actuated, the fire door will automatically close at a rate that meets NFPA 80 regulations. You can also get retrofit fire door operators that are compliant with all UL fire rating standards to work with many common manufacturer’s fire doors.

When installing fire doors, the automatic closing of the door must be tested. Annual drop tests are required on fire doors and a pre-drop test inspection must be performed to ensure there is no damage to guides, curtain and endlocks, bottom bar, hood and operating mechanism. When drop testing, it must be done twice and the door must close completely and rest on the sill. Once to verify proper operation and full closure, and a second time to verify that the automatic closing device was properly reset. NFPA 80 states that the average closing speed must not exceed 24 inches per second and must be at least 6 inches per second.

Types of Doors

Commercial Counter Shutter Doors and Commercial Rolling Steel Garage Doors

Compatible Accessories

Single Button Control

Auxiliary Limit Switches

Interlock Switch

Remote Control

Loop Detectors, Probes and Radar

Commercial Garage Door Opener Common Repairs

- Power supply

- Misaligned photo eye

- Chain

- Receivers

- Relays

- Motors

- Switches

- Belts

- Connectivity with access control and/or key fob systems

- Damage to the track

- Sprockets

- Wall controls

- Transformers

- Gearboxes

- Circuit boards

Commercial Garage Door Operator Maintenance

It is recommended to lubricate all moving parts every six months on a semi-annual basis. Maintenance should be performed more often if operators are cycling more frequently. LiftMaster recommends every 3 months or 5,000 cycles.

- Lubrication chains, bearings and limit shaft and checking for wear and slack. If chain adjustment is required verify and adjust limit switches, if necessary.

- Verify that motor, solenoid and operator runs smoothly and quietly.

- Verify tightness of all fasteners and set screws.

- Verify the operator is properly secured.

- Inspect manual disconnect.

- Verify tension and condition of all belts.

- Verify that inside of control box is clean and that grounding wires, terminations and power termination do not show signs of corrosion.

- Verify tightness of all terminal strip screws and electrical connections.

- Verify power supply, voltage of input terminals during operation.

- Checking gearbox integrity and oil levels (heavier duty openers, manufacturer specific).

- Checking clutch and brake tightness (trolley or jackshaft openers).

- Testing safety devices.

- Testing egress devices.

- Test chain hoist models for operation