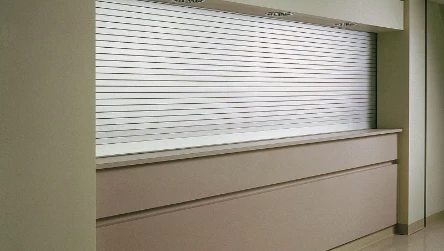

Pharmacies, hospitality spaces, concession areas at arenas/educational facilities, cafeterias, parts counters and tool area storage are great examples of spaces that would want counter shutters installed. Benefits include a custom, built-in look and vinyl graphics can be applied to the curtain and hood for logos and advertisements to be displayed. Counter shutters are also available in fire-rated models designed for you to protect against the spread of smoke and fire.

Commercial Service Doors FAQ

-

Counter Shutter Features & Options – Storefront or Counter Option

- Flush or ribbed curtain slats with galvanized steel, aluminum or stainless steel curtain options.

- Vision windows available – one-way or two-way option.

- Finishes – Powder coat finish in more than 180 colors is available on perimeter components including the curtain, aluminum bottom bar, hoods, wall angles, tubes and fascia.

- Higher Cycle Springs for commercial application recommended starting at 25K (10K-100K cycle options).

- Operation – Push up, hand chain, internal or external motor operation are available based on size and weight. Lifting the counter door requires no more than 25lbs of force. Concealed tubular motors provide a solution for strict dimensional limitations around the header or aesthetic requirements that lend themselves to its smaller, compact design.

- Trim package available.

- A variety of locking options to meet your needs.

- Manual release system – If egress is required on a motorized counter shutter, a wall mounted pull handle disengages the motor to allow the shutter to partially open.

- Fire-Rated Counter Shutters – Approved wall types for the mounting of fire-rated doors include masonry or structural steel jambs.

- Doors can be designed to meet specific PSF wind Load requirements.

-

Counter Shutter Common Repairs

- Curtain misalignment.

- Spring barrel replacement and hood bracket replacement.

- Full curtain and/or worn or damaged slats.

- Guide repair or replacement.

- Bottom locking bar and astragal replacement.

- Coil replacement on fire-rated counter shutters.

- Safety sensor misalignment (if automated) or Miller’s Edge malfunctioning.

- Chain for chain hoist replacement.

- Push button replacement (if automated).

-

Counter Shutter Maintenance

It is recommended to lubricate all moving parts every six months to one year. More frequent use doors will require more frequent lubrication. Regular maintenance should include checking the following items:

- Inspect curtain and bracket alignment and ensure it is level and is moving through opening smoothly.

- Check curtain components (slats and endlocks).

- Inspect fasteners connecting curtain to barrel are in place and securely fastened

- Check to ensure hood isn’t dented or damaged and/or rubbing against the curtain and that the hood is level.

- Inspect bottom bar and fasteners to ensure in place and make sure it is tightened and not damaged.

- Inspect guides and hood for damage.

- Check spring tension in the spring barrel.

- Inspect and lubricate bearings.

- Check sprockets and sprocket key for alignment and ensure it is fastened with set screws.

- Inspect stops to ensure none are missing, loose or broken.

- Inspect and lubricate chain hoist or commercial operator.

- Check sensing edge and/or safety sensors for proper functionality.

- See commercial operators for maintenance information.

Our Services

Areas We Serve

We’re here to bring fast, reliable garage door service to homeowners and businesses in the communities we proudly serve.